Our home is one of the safest places where almost all of us have found our solace and joy. The home is where we spend most of our day, knowing no matter what happens, we will be safe. But what is it about our home that makes it safe from psychological threats and physical as well?

It is cement. The more strongly amalgamated a segment is manufactured, the better and strengthened a house will be. It is in the cement that the magic of safety lies.

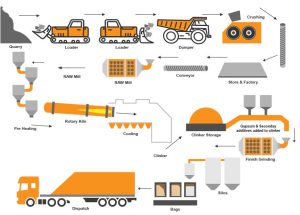

However, when it comes to how the cement is manufactured, very few know about it. Today we will discuss the dry process of cement manufacturing so that you can appreciate the bits that stayed unknown.

What is Dry Process Of Cement Manufacturing?

In dry and semi-dry processes for cement manufacturing, the raw materials will be crushed and then fed in the correct proportions. It is then added to the grinding mill. Then, the raw material will be dried and reduced in size to a fine powder in there.

The dry powder you will get there will be called the raw meal then, the raw meal will be pumped into a blending silo. It is here where all kinds of adjustments are made. The proportions of the materials are fixed here as well. In short, the manufacture of cement is done in a silo.

Then the raw meal will be blended by passing compressed air to obtain a coagulated and uniform mixture. Compressed air will be induced upward. The upward movement of the powder will decrease the apparent density. The air will then be pumped over the quadrant of the silo. This will permit the heavier material from the non-aerated quadrants.

Therefore, the aerated powder that you will acquire will behave like a liquid. A uniform mixture will be obtained if it is aerated through the quadrants in turn for at least one hour. In some cement manufacturing plants like Surya Gold, continuous blending is used.

The blended meal then will be further passed through a sieve. After getting it through the drive, it will be fed into a rotating disc called a granulator. Finally, the quantity of water, about 12 % by weight, will be added to it to be blended into pellets.

Semi-dry Process of Cement Manufacturing

The blended meal will be sieved and then fed into the rotating dish in a semi-dry process. It is known to us as the granulator. The water content in this will also be about 12% of the meal being added simultaneously. As a result, the hard pellet, which is supposed to be about 15 mm in diameter, will be formed.

It is one of the necessary procedures as the cold powder will be fed directly into the kiln. However, it would not permit the airflow and the exchange of the heat necessary for the chemical reactions of the formation of cement clinker. The pellets then will be baked hard in a pre-heating grate employing hot gases from the kiln.

The pellets would normally enter the kiln where the temperature will be as high as 1450°C. The total consumption of coal in this process that one may use may range from 100kg to 220 kg. However, it may depend on varying elements and specifications in producing a ton of cement in the wet process.

The dry material will undergo a series of chemical reactions in the hottest part of the kiln. Only 20–30% of it will become liquid, and lime, silica, and alumina recombine. The fused mass will turn into balls of diameter 3 to 25mm, which we will call clinker.

Ending note:

Now that you know the rigorous process of making cement, you will appreciate your home more.

FAQs and Answers

What is dry and wet process of cement?

The dry process of cement manufacture involves grinding and mixing raw materials, such as limestone and clay, into a powder and then heating the mixture to a temperature that causes the raw materials to react and form a hard, clinker material.

The wet process of cement manufacture involves grinding and mixing raw materials, such as limestone and clay, into a slurry and then heating the mixture to a temperature that causes the raw materials to react and form a hard, clinker material.

Which is better wet or dry process of cement?

It is difficult to say definitively which process is better for producing cement, as both the dry process and the wet process have their own advantages and disadvantages.

What is difference between dry and wet process?

The main difference between the dry process and wet process of cement manufacture is the way in which the raw materials are prepared before they are fed into the kiln.

In the dry process, the raw materials are ground and dried into a powder, which is then mixed and fed into the kiln. The raw materials are heated to a temperature that causes them to react and form clinker, which is a hard, grayish-black material that is ground into a fine powder to produce cement.